The exhibition came to a successful conclusion, and the semiconductor feast achieved fruitful results

The 2025 SEMICON Taiwan successfully concluded today at the Nangang Exhibition Center in Taipei. The scale of this exhibition has reached a historic high, with an exhibition area of over 20000 square meters, gathering 850 leading companies from 25 countries and regions around the world, and attracting more than 50000 professional visitors. The exhibition focuses on three major themes: artificial intelligence, advanced manufacturing, and green technology, comprehensively showcasing the latest technological achievements and development trends of the semiconductor industry chain, providing a platform for global industry elites to deeply exchange and cooperate.

Smart logistics solutions lead industrial innovation and transformation

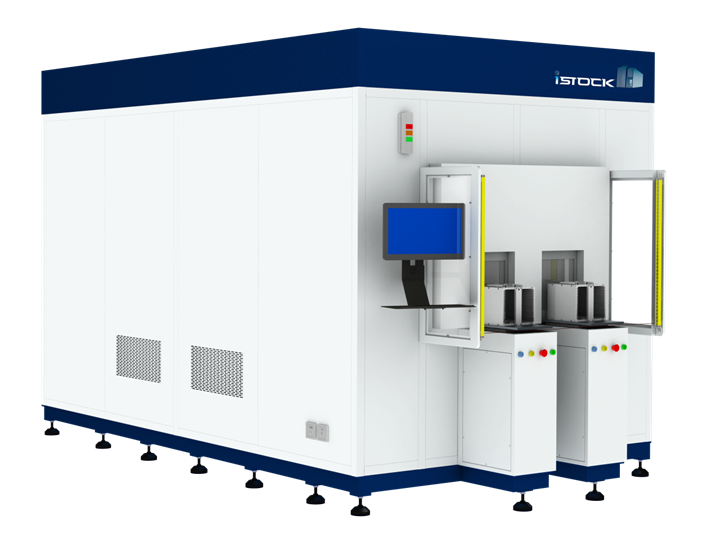

As an important participant in the field of semiconductor intelligent manufacturing, AstraZeneca unveiled its latest generation of intelligent logistics solutions. The system integrates cutting-edge technologies such as artificial intelligence scheduling algorithms, IoT perception technology, automation control, and digital twins, and is deeply optimized for the ultra-high cleanliness requirements, precision material management, and all-weather stable operation in the semiconductor manufacturing environment. The dynamic operation of equipment and real-time data visualization on television vividly demonstrate the company's technological strength in the field of semiconductor intelligent logistics.As an important participant in the field of semiconductor intelligent manufacturing, i-Stock company presents its latest generation of intelligent logistics solutions in a grand manner. The system integrates cutting-edge technologies such as artificial intelligence scheduling algorithms, IoT perception technology, automation control, and digital twins, and is deeply optimized for the ultra-high cleanliness requirements, precision material management, and all-weather stable operation in the semiconductor manufacturing environment. The dynamic operation of equipment and real-time data visualization on television vividly demonstrate the company's technological strength in the field of semiconductor intelligent logistics.

The technical strength has been recognized, and the on-site response at the booth has been enthusiastic

During the exhibition, the Aisdak booth remained extremely popular, with a continuous stream of professional visitors coming to inquire and negotiate. The company's technical team received many technical experts and executives from globally renowned semiconductor companies, and had in-depth exchanges on the application of intelligent warehousing systems in specific scenarios such as wafer production and advanced packaging testing. Many customers have shown strong interest in the system's support for multi plant collaborative management, real-time temperature and humidity monitoring, and nitrogen management functions.During the exhibition, the i-Stock booth remained extremely popular, with a continuous stream of professional visitors coming to inquire and negotiate. The company's technical team received many technical experts and executives from globally renowned semiconductor companies, and had in-depth exchanges on the application of intelligent warehousing systems in specific scenarios such as wafer production and advanced packaging testing. Many customers have shown strong interest in the system's support for multi plant collaborative management, real-time temperature and humidity monitoring, and nitrogen management functions.

Deeply cultivating the semiconductor field and helping the industry transform and upgrade

I-Stock has been deeply involved in intelligent logistics solutions for the semiconductor industry for many years, and has a deep understanding of the industry's special requirements for material management. The solution exhibited this time supports up to Class 10 clean environment operation, enabling millimeter level precise positioning and full traceability management of precision materials such as wafer carriers and photomask boxes. The system can also seamlessly integrate with production management systems such as MES and ERP, building a complete intelligent manufacturing ecosystem for enterprises and helping semiconductor companies achieve warehousing, reduce operating costs, and improve material turnover efficiency.

Seize market opportunities and create a better future for the industry together

As an important base for the global semiconductor industry, Taiwan's semiconductor output value will exceed NT $5 trillion by 2024, occupying a pivotal position in the global industrial chain. With the rapid development of emerging applications such as artificial intelligence, the Internet of Things, and new energy vehicles, the demand for intelligence and automation in the semiconductor industry continues to increase. i-Stock will continue to increase research and development investment, deepen strategic cooperation with local enterprises, and contribute more innovative solutions to promote the intelligent upgrading of the semiconductor industry.

Although Semicon Taiwan 2025 has come to a successful conclusion, i-Stock's innovative pace has never stopped. The company will continue to be driven by technological innovation and work together with global partners to promote the development of the semiconductor industry towards a smarter, more efficient, and more sustainable direction, laying a solid foundation for building the future digital world.