Conference Introduction

In 2024, Hefei ICV industrial cluster's revenue growth trend will be encouraging. In 2025, it will continue to deepen the construction of the "core screen steam integration" and "urgent life-long intelligence" industrial system, vigorously promote the landing of key industrial projects, promote the operation of the ICV testing and certification platform, industrial Internet innovation center, coordinate the cultivation of emerging industries such as quantum technology, artificial intelligence, biomedicine, and accelerate the construction of a high-level modern industrial system. A solid foundation in intelligent manufacturing is the fertile ground for the development of the artificial intelligence industry. Hefei is located in the core area of Changsanjiao Intelligent Manufacturing and has well-known intelligent manufacturing enterprises such as Lianbao, BOE, and NIO. In the field of intelligent terminals, Hefei's related products occupy an important position in the market, laying a solid foundation for Hefei to accelerate the construction of a national level intelligent manufacturing industry highland.

On August 14, 2025, the Step by Step New Technology Seminar will be held in Hefei, with the theme of "Intelligent Factory and Reliability Improvement Plan in the AI+Era" at the Hefei Calligraphy Building. The seminar will be aimed at the electronic manufacturing industry audience in the middle reaches of the Yangtze River urban agglomeration, committed to promoting the development of the electronic manufacturing industry in Anhui Province, gathering first-class intelligent manufacturing resources at home and abroad, promoting exchanges, establishing an intelligent manufacturing industry service platform that is in line with international standards, empowering the further upgrading of intelligent manufacturing in Hefei, and helping Hefei achieve higher quality development in the field of intelligent manufacturing. We sincerely invite you to attend the conference.

Meeting Agenda

Product recommendation

Product Introduction

I-Stock ll Pro is a product developed and upgraded by the i-Stock technical team based on its original foundation. It has gained a strong reputation for its high capacity, high efficiency, and dual robotic arms. The design of three deep storage locations has increased the storage quantity of materials by three times. In addition, in order to increase the storage capacity of the machine, i-Stock ll Pro also increases storage space by adding intermediate modules while retaining the original height and width. In terms of improving efficiency, the i-Stock technical team has planned a robotic arm for i-Stock ll Pro that can take three trays of materials at once, a dual robotic arm that can feed and discharge materials simultaneously or simultaneously without interfering with each other, and dual material ports that can feed and discharge materials simultaneously, thus improving efficiency.

Product parameters

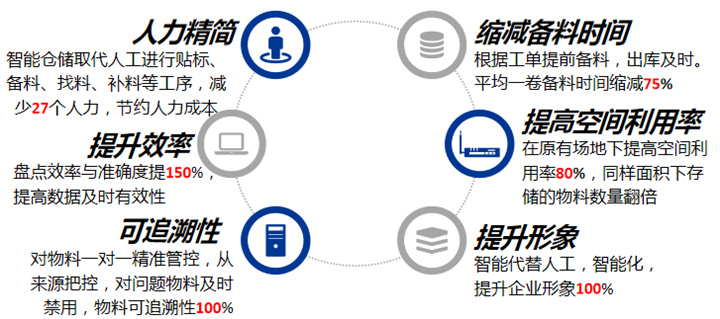

Product advantages

I-Stock always adheres to customer needs as the core, driven by intelligent equipment and precision technology, industrial software connects data flow, data+AI algorithm empowers smart warehousing in the electronics and semiconductor industries, focuses on product quality, and serves with dedication.

I-Stock helps enterprises solve practical problems encountered in the scientific, standardized, digital, automated, and intelligent upgrading of intelligent warehousing, and provides customized services for intelligent warehousing equipment.

In the future, i-Stock will continue to leverage its advantages in technology, talent, and resources to contribute to the transformation and upgrading of China's manufacturing industry. In this process, i-Stock will help more enterprises to enter the lighthouse factory, work together, and jointly promote China's manufacturing industry to move towards the top of the global value chain.